Pouya Sanat Crusher Atlas Chain feeder

The chain feeder Pouya Sanat Crusher Atlasr is one of the important products of Poya Sanat Atlas Crusher Company. This device is used to feed and transfer minerals and stones to stone crushers and plays a vital role in the process of crushing materials.

Components and performance

- Pouya Sanat Crusher Atlas Chain feeder:

- Chains: using high-quality and resistant chains to carry heavy and bulky materials.

- Motor: powerful motors to provide the power of moving chains.

- Impact Plates: Wear-resistant plates to reduce impacts and protect chains.

- Feeder tray:

- Heavy-duty trays: Made of wear-resistant steel to guide material to the crusher.

- Adjusting the feeding rate: the ability to accurately adjust the speed of the chains and the size of the tray to control the feeding rate.

- Vibration system:

- Vibrating motors: special motors to vibrate and help move materials better.

- Suspension system: to reduce the transmission of vibration to the main structure of the machine and the bases.

Benefits

- Carrying heavy and bulky materials: the dynamic chain feeder of the Atlas crusher industry has the ability to carry very heavy materials using strong chains.

- Precise control of feeding: the possibility of adjusting the speed of chains for precise control of feeding to the stone crusher.

- High wear resistance: use of resistant materials in the construction of feeder components to increase the useful life of the device.

- Performance in harsh conditions: Excellent performance in harsh industrial environments and difficult conditions.

Applications

- Mining industry: feeding stone crushers with minerals and stones.

- Construction industry: moving and crushing building materials such as building stones and concrete.

- Other industries: Application in moving and feeding heavy and bulky materials in various industries.

Maintenance and repairs

Regular maintenance and repairs of the dynamic chain feeder of the Atlas crusher industry is very important:

- Regular inspection of chains: ensuring that the chains are in good condition and not excessively worn.

- Replacement of shock plates: If necessary, replacement of shock plates to prevent damage to the chains.

- Motors and vibration system control: ensuring the correct operation of motors and vibration system.

- Lubrication: Regular lubrication of chains and moving parts to prevent wear and tear.

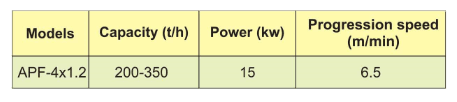

Using the dynamic chain feeder of the Atlas crushing industry in industrial processes is a smart and effective choice due to its high efficiency and resistance to harsh conditions. According to the specific needs of each industry, these devices can be adjusted and used with different specifications and sizes.